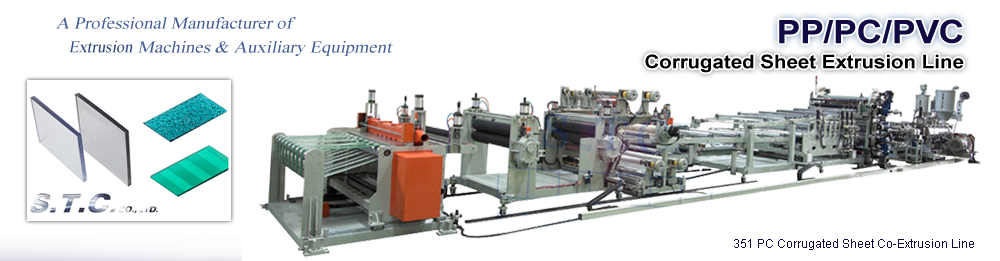

Transparent PC hollow plate is a type of engineering plastic plate material with extremely good comprehensive performance, and a material widely applied internationally nowadays with high strength, good light permeation, sound isolation and energy saving properties. The hollow plates also have many advantages of lightweight, roughing and resisting to abrasion, moisture and corrosion proof, isolating from heat and vibration, and easy for processing.

The flexibility and plasticity of PC hollow plates make them an ideal material for domes and other curved surfaces. The minimum bending radius can be 175 times of the plate thickness(bending radius ?175 thickness).

| |

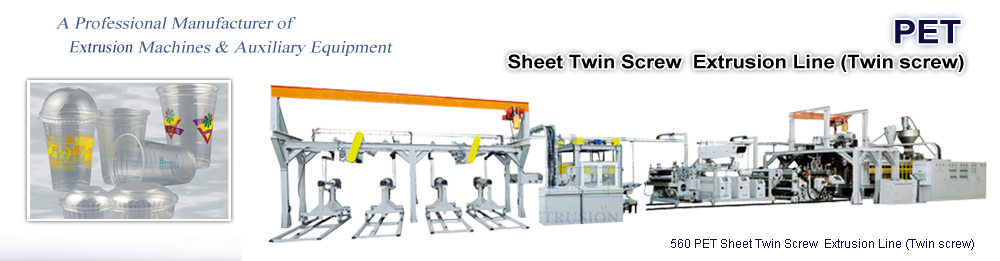

| Specification / Model No:

130 |

Update: 2004/06 |

|

| Content |

Specification |

| Main extruder |

| Screw diameter |

120mm |

| Screw L/D ratio |

33:1 |

| Barrel temperature control |

7 zones |

| Motor |

250 HP made in Italy |

| Screen changer |

1 set |

| Gear pump |

1 set |

| Static mixer |

1 set |

| UV extruder |

| Screw diameter |

35mm |

| Screw L/D ratio |

28:1 |

| Barrel temperature control |

3 zones |

| Motor |

20 HP |

| Screen changer |

1 set |

| Gear pump |

1 set |

| Static mixer |

1 set |

| Feedblock |

1 set |

| T-Die |

| width |

2200 mm |

| Product thickness |

4, 6, 8,10 mm |

| Vacuum forming platform |

| Temperature controller |

3 sets |

| First taking roller unit |

1 set |

| Oven unit |

1 set |

| Film laminating unit |

1 set |

| Slitting unit |

1 set |

| Second taking roller unit |

1 set |

| Crosscutting unit |

1 set |

| Stacker |

1 set |

| Electricity control cabinet |

Adopt SSR and PLC system |

| Total weight |

55 Tons approximately |

| Occupied ground area |

30000mm×4125mm×2095mm(L×W×H) |

|

| PS. We can manufacture the machine depend on customer’s request. |

| |